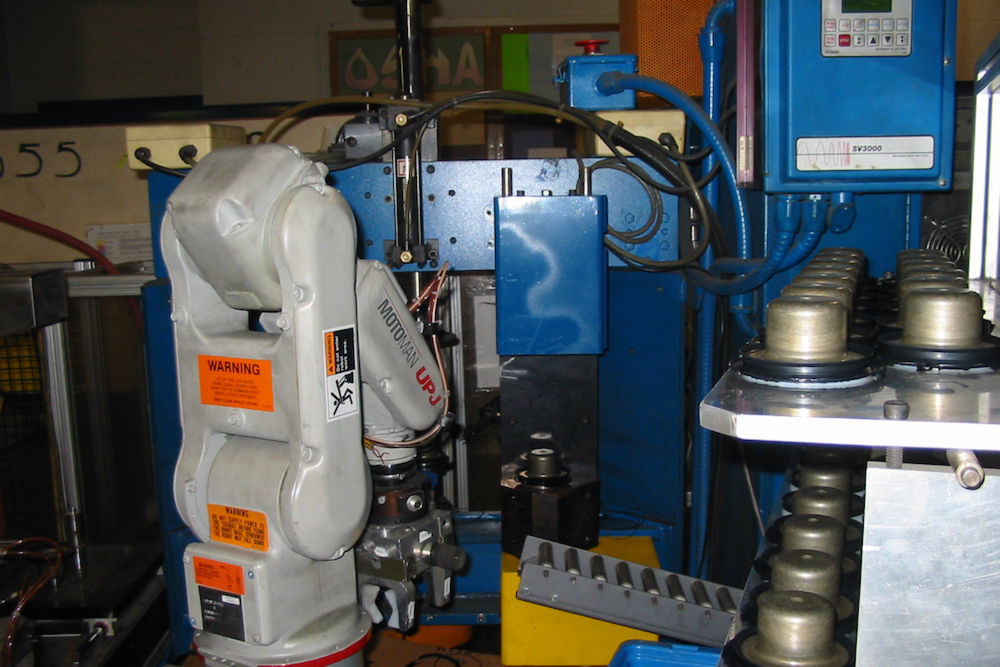

Pallet Handling

This project was a great challenge. The customer wanted to very gently transport full product pallets from the automatic Robotic palletizing cells into the strapping machines. The pallets that were not secured yet were at a height of 107 inches. We designed this system electrically and mechanically. We designed all of the controls to be over Ethernet for ease of wiring, installation and integration. We had 70 conveyor sections on this project, all with variable frequency drives, and utilizing safety over Ethernet on all of them. The system was so large, we had to have (3) operator interfaces to break it up so it was more user friendly. It has been in production for over a year. Also, this project was out the country, so we had to build and label it Ce in order to meet the requirements of where it was going to be.